PROGRESS ENGINEERING AND PRODUCT CO.,LTD.

ORGANIC FERTILIZER MACHINE "LION1"

"EASY TO GRANULATE. EVERYONE CAN DO"

TH | EN

|

PROGRESS ENGINEERING AND PRODUCT CO.,LTD. ORGANIC FERTILIZER MACHINE "LION1" "EASY TO GRANULATE. EVERYONE CAN DO" TH | EN |

Comparison of organic fertilizer granulators Methods of making fertilizer granules in general can be categorized into 2 types as follows. 1. Granules making 2. Pellet pressing |

||

| Granules making | ||

|

The type of machines mostly used is circle-dish granule making machine. Principle Fertilizer granule making by a circle-dish relies on gravity that pulls objects towards the center of the planet. In other words, objects always fall down. Therefore, if we pour fertilizer powder from the top of the circle-dish, the fertilizer will fall or roll down along the dish surface. While fertilizer powder falling, given suitable humid, the fertilizer will gradually becomes bigger fertilizer granules. | |

|

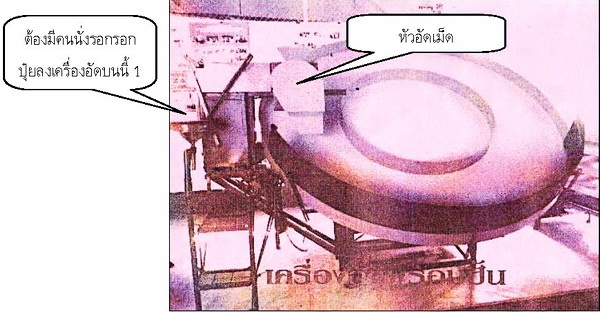

To make a continuous fertilizer granule making process, a circle-dish is used by pouring down fertilizer powder on top. As the dish spins, the fertilizer will roll on the dish surface. During that, spray water until fertilizer is humid and becomes granules. Point to Observe: This circle-dish is separated into 2 rings. The fertilizer powder is poured into the inner ring and sprayed so it becomes granules within this inner ring. The outer ring is used for making the granules round and smooth. Human labors holding a spade are used to take out the granules with proper size from the inner ring and put them into the outer ring to let them roll and become round and smooth. | |

When the granules are round and smooth, human labors are used again in taking out the granules of the dish as the final step of making fertilizer granules. Alternatively, in case of no human labors, when the dish is full of fertilizer granules, they will automatically fall out of the dish. | ||

Fertilizer granules are left to automatically fall out of the circle-dish. Fertilizer granules made by the circle-dish are in different sizes. |

||

| Strength of Granulating Circle-Dish 1.The fertilizer granules are round and smooth. |

Weaknesses of Granulating Circle-Dish 1.Fertilizer granulating depends on various factors as follows. 1.1 Fertilizer powder used for granulating by a circle-dish must be delicate enough to stick together. Big or rough texture is difficult to roll and become granules. 1.2 The fertilizer must have proper weight because circle-dish granulator relies on the gravity. If fertilizer mass is light, it will not roll but only slips along the dish surface and hardly becomes granules. A solution widely used is mixing fertilizer with soil as reported in the news. 1.3 Water sprayed on fertilizer powder must be constantly and thoroughly, not making any particular spots too wet. In addition, as there is only one just right level, it is difficult for some first-timers. Despite of the same type of fertilizer, in a different season, it is different in the way of spraying water. This makes water pump and sprayer necessary for circle-dish system. 1.4 There is no standard for setting the inclination of the circle-dish. The only person who determines the degree of the dish inclination is the one who holds the spade or a water sprayer. The inclination of the circle-dish also depends on the speed of the dish rotation. Conclusion It is difficult to make organic fertilizer granules with OM according to standard. 2.It is difficult to control the size of granules because they depend on the way fertilizer powder rolls. The more it rolls, the bigger the granule becomes. As a result, the sizes of fertilizer granules will definitely become different. The further the granule is away from the dish center, the bigger it becomes. This is because these granules have longer distance to roll than those at the dish center. The person making granules may be unable to do anything with this. Consequently, there must be fertilizer granules filter to take back the big ones and pound them before re-granulating. For example, if saying that the amount of granules made is 5 ton, it means 2 ton is taken out and only 3 ton left.  This machine is called fertilizer grading machine. In fact, it should be called fertilizer size sorting machine because, without this process, the fertilizer will be useless. 3. To handle the problem in No.2, pressing roller system has been developed as in the picture. |

|

| ||

| In order to get rid of the different sizes problem, a fertilizer pressing machine with spiral nozzle has been developed. This machine operates by pressing fertilizer powder trough a flange and cut it with a wire to get them in the same size. Then, use a pellet making dish to make those granules round. However, there is another problem as follows. 3.1 The process is not run smoothly. This is because the fertilizer is mixed somewhere else and put in a bucket for carrying it to another person to put it into the machine. It is not so modern and wastes staff’s energy. 3.2 The pressing machine has too much trouble to use. It always gets stuck and has to be cleaned or washed all the time. This is because the quality of the pressing machine is low as a small motor is used and even connected to the rolling dish. To summarize, the machine designer might not possess engineering knowledge. 3.3 The production rate is very low at not more than 1.5 tons per day (8 hours). 3.4 All motors used have low quality. 4.The pressing dish needs to be huge to provide a wide space for fertilizer granules to roll. Therefore, the production house must be big and high. Especially those with a conveyor belt need to be even bigger. In conclusion, this machine requires a lot of space. 5.This machine creates dirty working environment causing a lot of dust and pollution, which is dangerous for health. | ||

| ||

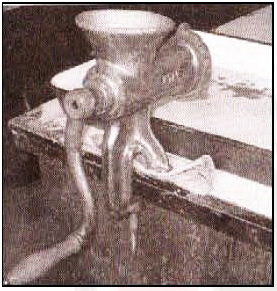

| Pellet pressing The machine used includes: 1. Mincer Type | ||

|

| |

|

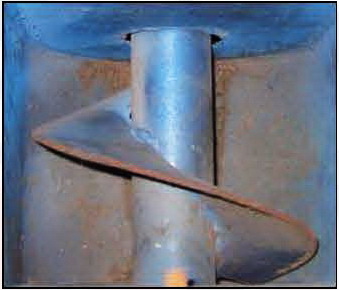

Principle: The machine consist of the followings. 1. Cylinder made of metal 2. Screw feeder in a size similar to the grinder’s 3. Flange |

||

Cylinder Screw feeder Flange |

||

Since the screw feeder is spiral spinning inside the Cylinder, the fertilizer is pushed by the spiral out of the flange holes. This causes the fertilizer to be tightly pressed and flows through the flange holes as stripes as in the picture. | ||

|

|

|

Strength 1. Big and rough fertilizer granules can be pressed into pellet. |

Weakness 1. The fertilizer pellet is in strips which look like feed as it is pressed through the holes most of which are big as they are easier than small ones. 2. The pellet is dry, hard, strip-shaped, insoluble, and impossible to contain it in a sprayer. 3. Since the pressure is high, an effective machine must have a motor with very high power. 4. The Screw feeder’s core easily wears away. 5. The flange also wears quickly and needs to be replaced often. 6. The production rate is very low and not suitable with fertilizer industry. |

|

There is a machine made abroad with the same principle but costing hundreds million Baht and using hundreds horse powers. The screw feeder’s core is slender which produces high pressure. | ||

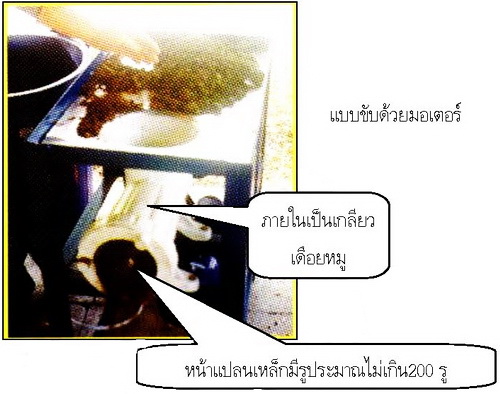

| 2. PELLET MILL | ||

| ||

|

Principle When the cover is open, 2 fertilizer rollers can be seen spinning around the core so that the rollers press at the cylinder’s inner side. If there is fertilizer, it will be pressed and pushed out beside the cylinder with holes. The flowing fertilizer will be cut into strips by wire. | |

| ||

Strength 1. Big and rough fertilizer can be made into pellet. |

Weakness 1. The pellet is dry, hard, strip-shaped, insoluble, and impossible to contain it in a sprayer. 2. The roller and grinder easily wear away. 3. The machine is not durable especially at the key part which is the roller. 4. The parts are separated into pieces and the process is not continuous. | |

Summary Each type of fertilizer making machines has the following characteristics. 1. The manufacturers do not develop their own ideas but usually copy or imitate big machines so they are unable to operate smoothly. 2. The design is done for part by part without continuous process so it wastes energy and costs more expense if any tools need to be added. Also, the machine costs a lot. 3. The design of the machine or the parts does not consider of using a universal outlook or machine-like appearance. Instead, bits of steel or leftover materials are recycled and used for making the machine such as an example in the picture.  4. The parts used such as bearing, motors, or others are cheap stuff with low quality. | ||

ORGANIC FERTILIZER MACHINE "LION1" | ||

| ||

| Lion One organic fertilizer pallet mill combines granulating and pressing methods together. Additionally, it has been designed according to engineering principles, which improves almost every weakness as can be detailed as below. | ||

1.Fertilizer pellet making must be easy for everyone. Lion One designed the machine to operate continuously and quite automatically. In other words, after putting in fertilizer powder at the starting point, the fertilizer pellets will come out at the end right away since the machine can be left to work by itself. | ||

|

At the starting point is the fertilizer mixing tanks designed to be double tanks for continuous operation. Organic substances are mixed with plant nutrients added with some humid to make fertilizer stick together. Such mixing is done in two tanks at the same time. However, the fertilizer powder is released into the system tank by tank. Therefore, there is mixed fertilizer in one tank waiting. After the first one is empty, the mixture in the second one is released. During this, the fertilizer is mixed in the first tank to stand by. The operation goes on this way continuously. Mixing fertilizer in these tanks is very easy because the operator only needs to remember the ratio of ingredients including how much kg of fertilizer powder and nutrients, and water for increasing humidity by using only one container. The operator is able to put all the ingredients into the tank immediately without spraying water since there is a mixing tool to make the ingredients thoroughly and well combined with equal humidity all over. It can be said that anyone who can lift 40 kg fertilizer, put in 5 kg of dolomite and 10 liter of water is able to make fertilizer. As easy as it is, “anyone can do it”. | |

2. Fertilizer pellet is controlled to be in the same size. | ||

|

Lion One uses double rollers system following engineering principle. These rollers run and press fertilizer powder on the grill (holes size of 5 mm). When there is fertilizer on the grill, it will be pressed by the rollers and flow through the grill holes to the bottom. The roller’ pressure is even because of the spring which makes the pellet of Lion One not too tight as those made by other pellet pressing systems. The fertilizer pellet made by Lion One machine is easily soluble but not broken in the bag. | |

|

Underneath the grill, there is stainless wire revolving in the same direction with the rollers. Therefore, when fertilizer strips flow down, the wire will cut them into the same length. With such system mentioned, organic fertilizer can be made without mixing soil. | |

| ||

The cut fertilizer pellet will fall into the swirling aluminum inclining tray with an open end. Therefore, fertilizer pellets will roll around and flow out at the end of the tray. This makes the pellet round and smooth. In the new system, Lion One uses spinning tube which is thick and durable plastic for making the pellet round and smooth with the same size as in the picture. To summarize, Lion One can definitely control the fertilizer pellet size by an easy method without any special skills needed. |

| |

3. Lion One is designed to be the true agricultural machine. | ||

3.1 Bucket and chain are used in transportation system *not occupying a lot of space like conveyor belt system *easy to maintain and able to repair only at the broken parts without changing the whole line *having digital speed adjuster in version 2 model, which is easier to operate |

| |

3.2 Independent electricity control switchboard *using magnetic control switchboard in turning on the motor, not only using breaker *having operation indicator lamp of each set *having emergency switch for immediate pause *having digital speed control. |

| |

3.3 User’s safety system *Each installation of machines, ground motor and ground connection will be set up to prevent dangers from electrical leak and shock. | ||

| ||

3.4 The machine parts can be separated and re-assembled for the convenience of transportation. 3.5 Colored parts use powder coating, which provides high quality color according to standard and durable for scratches. 3.6 Old materials will definitely not be used in making Lion One machines. 3.7 There is no policy of making a refined machine by using steel bits as the parts. 3.8 High quality motors and parts are used since low quality materials are not worth repairing. 3.9 Possessing a patent of invention and not copying any other companies | ||

Finally, we would like you to figure out the followings: *Why don’t other fertilizer granulators have their own brand or no patent? *Buying cheap parts to combine is still expensive in total? *For using purpose, buy Lion One machine. *Why is Benz more expensive than Toyota? *There is only Lion One that allows buyers to try making granules and feel confident before buying. | ||

|

||||||||||||||||||||||||||||||

© 2012 PROGRESS ENGINEERING AND PRODUCTS CO.,LTD |